Feeds and Speeds of Shop Bot

How Do Machinists Calculate Feeds and Speeds?

Feeds and speeds are important, because they're the key to Longer Tool Life, Faster Machining Speeds (through higher Material Removal Rates), and Better Surface Finish. But they involve a lot of different concepts, which can make them hard to learn.

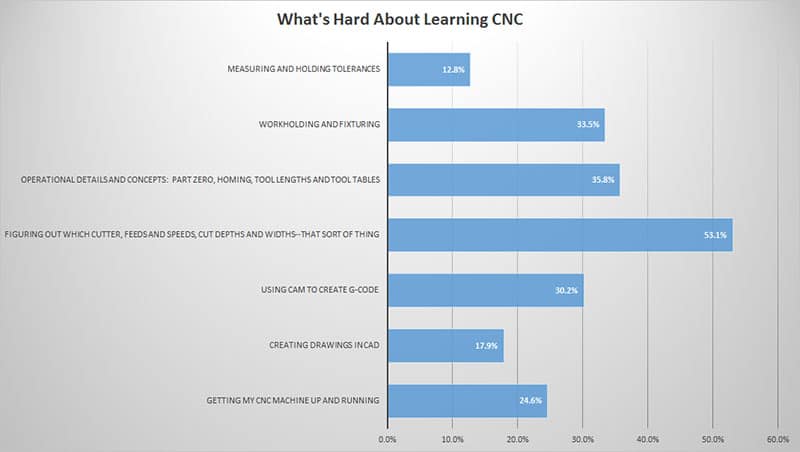

We surveyed our readers to ask experienced CNC'ers what the hardest CNC concepts and techiques to learn were, and here's what they said:

Feeds and Speeds are the hardest thing to learn in CNC…

The answer, by a wide margin, was that Feeds and Speeds are the hardest thing to learn in CNC. This Guide is here to make that learning curve much easier for you!

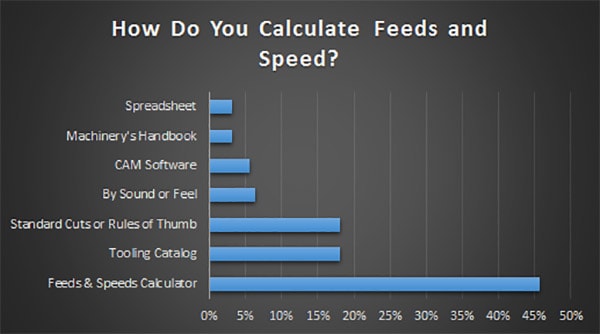

For starters, it's worth asking, "How do machinists determine Feeds and Speeds?" We surveyed our readership and here's what they said:

There are a number of approaches:

– You can build or borrow a spreadsheet. This is the least popular for reasons I'll discuss. Basically, it's a lot of work for a lot of limitations.

– About the same number use Machinery's Handbook. It's pretty antiquated, especially for CNC applications.

– Amazingly few use their CAM software, even though most CAM has provision for it. The reason is simple, and we uncovered in our CAM Software surveys. Most CAM software does a truly lousy job with feeds and speeds. It's pretty easy for you to do better.

– You can rely on sound or feel. This requires quite a lot of experience and even though it has its devotees, it basically doesn't work. If it did, you could buy "ear training" CD's for machinists and Boeing would require you to pass a feeds and speeds by ear audio test before they would hire you. None of that happens because you can only hear really bad feeds and speeds. You can't hear somewhat bad and you sure can't tell the difference between ok and really awesome feeds and speeds.

– You can rely on standard cuts that have worked in the past or rules of thumb. This method is pretty popular, but it sure is limiting. After all, are all of the pockets you cut the same depth? There are variances in every job and if you're locked into just a few standard cuts, you're missing out on the possibilities. BTW, one of the reasons CAM does such a lousy job is it takes the approach of databasing standard cuts. Every job is different.

– You can rely on data from the Tooling Catalog feeds and speeds chart. That data is important, but used by itself, it's also loaded with limitations. For example, a feeds and speeds chart is a 2 dimensional table. It can only cover 2 variables. Our G-Wizard Feeds and Speeds Calculator covers 60 variables! When was the last time you looked through 30 charts to figure feeds and speeds? You basically can't do it, which is why:

– By far the most popular option is to use a Feeds & Speeds Calculator such as our G-Wizard. If you're ready to accept a Feeds and Speeds Calculator and want to move on and learn other things, click here. If you want to know more about other options, keep reading.

Why can't I just ask other experienced CNC'ers about their Feeds and Speeds?

You see this all the time on the Internet in the forums. Someone wants to know the best Feeds and Speeds for some new material or with some new tool. You can even spend money to join a service where experts will give you their tested recipes, complete with videos so you know it works.

Oh my! These things are all so limited, time consuming, and potentially expensive.

The first problem is you have no idea what kind of quality you're getting from these outside sources. What were their criteria for testing? How thoroughly did they test?

Even when you have a video, you don't really know unless they test to destruction of the tool in the video much more than that on that particular machine, when the tool was set up by that particular person, with that particular material, the tool lasted long enough to make the video. You have no idea how much deflection was there (I call tool deflection the "silent tool killer") or what kind of shape the cutter was in when finished.

And those guys you ask on the Internet? You really have no idea what's going on there.

To be a successful CNC'er, you need to be in control of your feeds and speeds. You need to be able to get your hands on good feeds and speeds for your machine, tooling, materials, and best practices any time you need it.

Can I do those "Basic Formula" calculations, perhaps in a spreadsheet?

Absolutely! All the information is available. But, and this is important, there is a lot more going on than the simple formulas used to derive cnc feed rate and spindle rpm can account for. In the spirit of full disclosure, you can find the simple formulas in a lot of places, but I'll link to Wikipedia.

These formulas accept as inputs surface speed and tool diameter to calculate spindle rpm, and they accept number of flutes, spindle rpm, and chip load to calculate cnc feed rate. In fact, I even built a calculator using just the simple formulas and made it available online for free. Check it out:

[ Simple Formula Milling Speeds and Feeds Calculator ]

[ Simple Formula Drilling Speeds and Feeds Calculator ]

Seems easy, so where is the problem?

Well, there are a lot of obscure physics involved in cutting.

For example, there's something called "radial chip thinning". I'll explain it below, but those formulas on Wikipedia don't account for chip thinning, so anytime you're cutting less than half the diameter of the cutter as your stepover or cut width, they're wrong.

The thinner the cut, the more they're wrong, and ultimately they will be very wrong. By wrong I mean that if you use those Feeds and Speeds they're going to wear out your cutter prematurely. So, you'll need to go research the formulas for chip thinning so you can add them too.

You'll also want to find a large table of materials, with chip loads and surface speeds. Ideally your table is large enough to be a materials database that considers not just broad classes of materials, but individual alloys as well as the condition of the alloy, and adjusts the figures accordingly.

You will want to scale back your figures if you are slotting. In fact, you want to adjust based on how wide the cut is as well as how deep. There are manufacturer's tables out there to help you do that, it's just one more step to add to your process.

Speaking of steps, this stuff all adds up, and eventually, you have an awful lot of steps to be punching numbers into a calculator while rabidly flipping back and forth to look at various charts. For this approach, you could use an Excel spreadsheet. In fact, that's how my G-Wizard feeds and speeds software started out, but I'll warn you, you will outgrow Excel if you keep adding bells and whistles like I did.

Just so you know, G-Wizard Calculator considers almost 60 different variables. But it gets worse. Calculating any individual formula isn't bad. Even calculating 60 isn't the end of the world. But dealing with all their interactions, and especially backsolving is impossible in a spreadsheet. They're built to solve formulas in one direction only, and their ability to go backwards is severely limited.

Hey, I wrote one of the most popular spreadsheets back in the day called "Quattro Pro." I do know a thing or two about spreadsheets. Keep reading and I'll tell you why spreadsheets don't work and why I wound up writing G-Wizard Calculator instead.

What About Feeds and Speeds Calculators?

LOL, I thought you'd never ask (and I bet you figured I'd get here sooner or later because I sell software that calculates feeds and speeds).

Here's the thing, you can figure out everything you need to know to do what the software does and you can do it yourself. The data is all out there if you want to take the time to research it.

To write G-Wizard, I've probably gone through several hundred learned papers by PhD's and countless thousands of pages elsewhere on the Internet. I have standing Google searches that give me alerts every morning if someone publishes a new article about speeds and feeds that might be of interest. I've invested years building all of this into the G-Wizard software, so if you start today, it'll take you years to get something as sophisticated, by which time G-Wizard will have been improved further.

There are two big reasons why you'd want to look into a feeds and speeds calculator like G-Wizard:

1. They work and produce better results than simpler methods. The software can consider a whole lot more variables than you can punch into your desk calculator. It can present all that in a User Inteface that's much more efficient than a spreadsheet. And, it can do math that just simply isn't possible in a spreadsheet. All that will save you time and money, whether you're a hobbyist or a professional. And, if you're a beginner, it will also save you a lot of frustration.

2. Because you don't have the time to do all the research and the skills to build the software that brings it all together. Or even if you do, G-Wizard is cheap so why bother? Using a dedicated Feeds and Speeds calculator is fast and easy.

Here's a great video from the G-Wizard Video University that shows how to easily solve the hardest problem there is in CNC Feeds and Speeds with G-Wizard:

I won't belabor the point further other than to say I can't understand why every machinist wouldn't want to use a calculator of some kind (whether or not you choose G-Wizard). After all, who wouldn't want the best possible material removal rates, surface finish, or tool life?

Based on our survey results, I guess most machinists do realize they need a Feeds and Speeds Calculator. You can get your hands on the very best Feeds and Speeds Calculator available right now:  Check out just a few of the thousands of world-class manufacturers that are using G-Wizard today:

Check out just a few of the thousands of world-class manufacturers that are using G-Wizard today:

What's the Role of Manufacturer's Recommendations?

A number of machinists will pop up at this point and ask about Manufacturer's Recommendations. After all, doesn't the manufacturer know best how their tooling should be used?

The short answer is, "Yes, but it's more complex than that."

First, remember when we talked about cnc feeds and speeds charts being 2 dimensional? And remember how G-Wizard considers 60 variables? If you simply go by the feeds and speeds charts in tooling catalogs, you are missing a lot of variables.

But, there's a bigger issue: what are the manufacturers not telling you?

Some machinists have the perspective that their manufacturer is making claims that are aggressive for marketing reasons. They're suggesting outlandishly high feed rates and surface speeds that the tooling can't actually back up or that won't work right when the machinist tries them. This is true in some cases, but most manufacturers can't afford to do this very much. After all, if the cutters don't perform, are you going to reorder?

What they can afford to do is shade things towards the aggressive. After all, who is to say whether the numbers are a tad aggressive and the tool wears out a little quicker than it has to?

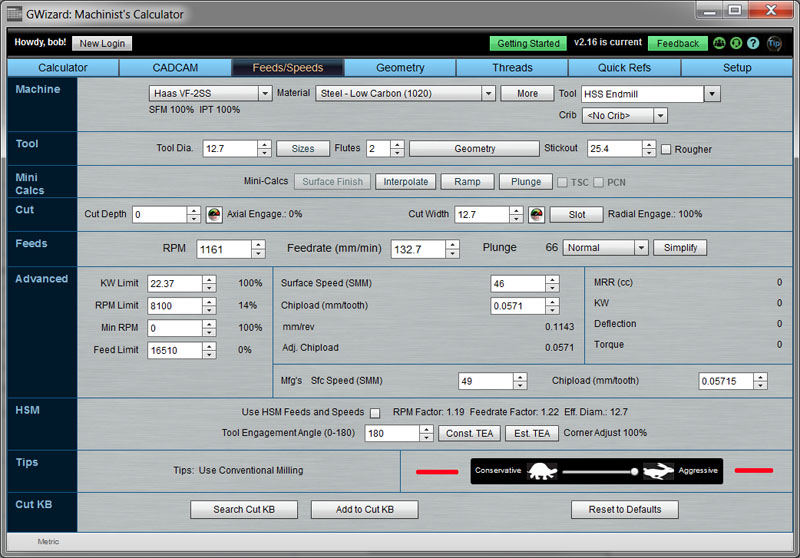

There are remedies for this. G-Wizard, for example, considers a lot of manufacturer's recommendations in an apples to apples match up (i.e. same coatings and geometries). It then does some very sophisticated number crunching to try to separate out the fact from the fiction. In other words, it tries to determine whether a manufacturer is overly aggressive (great MRR, lower tool life) or overly conservative (great tool life, lower MRR) to get to some "balanced" numbers. It does this by analyzing a minimum of 3 manufacturers for uncommonly used tools and 12-15 for commonly used tools (e.g. endmills or twist drills). It then provides a slider that lets you configure whether you're more interested in being conservative or aggressive:

The G-Wizard Gas Pedal or "Tortoise-Hare" Slider…

We call this feature the "Gas Pedal", and it is depicted by a tortoise and a hare, much like the old Bridgeport manual mills had for speed control. I'll talk more about how to use the Gas Pedal and how to think about how aggressive you want to be in the article "Toolroom vs Manufacturing Feeds and Speeds", which is the next article after this one.

Being able to make your own choices about whether to be conservative or aggressive is useful, but here is the real way to think about calculators and other machinist's software:It's all about how many variables you can master.

A basic Feeds and Speeds Chart like what's in your tooling catalog is a 2 dimensional entity. Therefore, it only covers 2 variables. They use multiple charts, add columns and rules of thumb to cover a few more variables–maybe 4 to 6.

Sophisticated feeds and speeds software lets you master a lot more variables than you could manage by hand. The more variables you can master, the more accurate your feeds and speeds. Every time you learn to master some additional variables, you can produce better results. G-Wizard is all about helping to master as many as possible. To give an idea of how crazy it gets, G-Wizard considers almost 60 different variables as it is making a speeds & feeds calculation.

Compare that to the half dozen considered by the Wikipedia formulas and you can start to understand the complexity behind modern feeds and speeds calculators. In addition to its 60 variables, it consults a total of 14 distinct databases. The total size of all that data makes G-Wizard the Calculator larger than G-Wizard the G-Code editor as I write this, even though the G-Code Editor is a far more complex piece of software.

It's the sheer volume of the databases that makes the Calculator larger. And, it's being able to consider all that data together with all those variables and do the math in the blink of an eye that produces the results. Let's go back to the Manufacturer's data one more time. Are we saying you should ignore it? I see two cases:

- You're a beginner or someone who doesn't care about getting the nth degree of performance from cutters. In that case, you should ignore Manufacturer's Data. G-Wizard's defaults are conservative and will do the right thing. Most users get faster cycle times and longer tool life from the defaults, anyway.

- You want every increment of performance you can get your hands on. You should be using the manufacturer's data. But, the way to think about it is that the data calibrates G-Wizard to work it's magic at an even higher level.

If you're in that latter camp and use a particular line of tooling as most shops do, you'll want your calculator to be able to import and use the manufacturer's data. Ideally it will import and use it along with all the other rules and formulas built in.

That last point is important: you need to apply all that math even if you have the manufacturer's data. Why? Because manufacturer's data has to be simplified in the interests of presentation.

Remember, a two dimensional table considers just 2 variables, perhaps material and tool diameter, for example, to look up surface speed and chip load. If you're lucky, they give you a couple of extra tables and maybe some rules of thumb:

– "These numbers are good to 1/2 diameter cut depth."

– "Reduce SFM 50% for full slotting or when cutting more than 2 x diameter deep."

You've surely seen such rules. Once again, a calculator can consider far more complex models. It can interpolate smoothly from 0 to the 2x diameter depth, adjusting all along the way. It can consider any cut width when figuring radial chip thinning instead of just the few in the manufacturer's tables.

This is valuable and leads to more performance no matter what you're trying to optimize for. The Manufacturer's data augments the 60 variables and 14 databases inside G-Wizard, it doesn't replace them. Also, manufacturers are fond of giving big ranges for surface speed and chipload and then telling you very little about how to select the best point within the range.

That's what G-Wizard is good at–giving an exact answer instead of a range.

So, enter your manufacturer's data into your calculator so it can add value to that data. G-Wizard lets you import the data as spreadsheet (CSV) files, to make it easy. It also includes a large catalog of downloadable manufacturer's data so you may not have to do any data entry at all. Lastly, if your calculator has tool table (tool crib) support and the ability to import manufacturer's data, they make ideal tools for comparing the performance of different tooling.

Resources

If you're still not convinced you need a Feeds and Speeds Calculator, try these resources:

Material Removal Rate [Optimizing MRR for Bigger Profits]

INFOGRAPHIC: Why You Need a Feeds and Speeds Calculator

11 Common Pitfalls of Simple Cutting Speed Formulas

preussfornevenithe.blogspot.com

Source: https://www.cnccookbook.com/feeds-speeds/

0 Response to "Feeds and Speeds of Shop Bot"

Post a Comment